Application

Rock formations:

Oilfield roller cone drill bits are widely used in various types of rock formations, including sandstone, shale, mudstone, and hard rocks. The choice of roller cone drill bit type depends on the hardness and properties of the rock formation.

Drilling objectives:

The drilling objectives also influence the selection of roller cone drill bits. For example, drilling oil wells and natural gas wells may require different types of drill bits to accommodate varying geological conditions and wellbore requirements.

Drilling speed:

The design and performance of roller cone drill bits directly affect drilling speed. When rapid drilling is required, it's crucial to select drill bits that offer high cutting efficiency and wear resistance.

Drilling environment:

Oilfield drilling often takes place in extreme environmental conditions, including high temperatures, high pressures, and high wear. Therefore, roller cone drill bits must be capable of continuous operation under these conditions and have a long service life.

In summary, the characteristics and applications of oilfield roller cone drill bits depend on geological conditions, drilling objectives, and environmental requirements. Proper selection and maintenance of roller cone drill bits are essential for improving drilling efficiency and reducing costs. These drill bits play a critical role in oilfield drilling and are of significant importance to the energy industry.

Characteristics

Material selection:

Oilfield roller cone drill bits are typically made from hard alloys (hard metals) as they need to operate in high-temperature, high-pressure, and high-wear environments. Hard alloys typically include cobalt and tungsten carbide components, which provide excellent hardness and wear resistance.

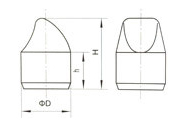

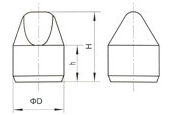

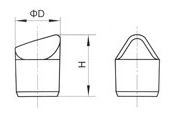

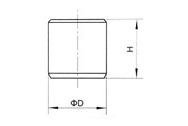

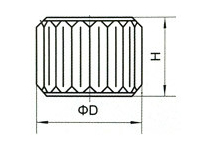

Taper and shape:

The shape and taper of roller cone drill bits can be adjusted to suit different geological conditions and drilling objectives. Common shapes include flat (milled tooth), round (insert tooth), and conical (tri-cone) to accommodate different types of rock formations.

Drill bit size:

The size of the drill bits can be chosen based on the diameter and depth of the wellbore to achieve optimal drilling performance. Larger drill bits are typically used for larger-diameter wellbores, while smaller ones are suitable for smaller-diameter wellbores.

Cutting structures:

Roller cone drill bits typically feature cutting structures such as protrusions, cutting edges, or chisel tips to cut and remove rock formations. The design and layout of these structures impact drilling speed and efficiency.

Material Information

| Grades | Density (g/cm³)±0.1 | Hardness (HRA)±1.0 |

Cobalt (%)±0.5 | TRS (MPa) | Recommended Application |

| KD603 | 13.95 | 85.5 | 2700 | Alloy teeth and drill bits with exposed and complex tooth structures, suitable for high drilling pressure, and adaptable to hard or complex geological conditions. | |

| KD453 | 14.2 | 86 | 2800 | Both of the height of open head of insert and the drilling pressure are in the middle, | |

| KD452 | 14.2 | 87.5 | 3000 | Both of the height of open head of inserts and the drilling pressure are in the middle, applied to drill the mid-hard or hard rock formation, its wear resistance is height than KD453 | |

| KD352C | 14.42 | 87.8 | 3000 | This material is intended for alloy teeth with exposed teeth and a simple tooth structure, suitable for geological conditions ranging from moderately hard to somewhat soft. | |

| KD302 | 14.5 | 88.6 | 3000 | Designed for low-profile drill bits with exposed teeth, a simple tooth structure, and suitable for the extraction of hard rock or non-ferrous metal ores. | |

| KD202M | 14.7 | 89.5 | 2600 | Applied to diameter keep inserts, back inserts, serrate inserts |

Product Specification

| Type | Dimensions | |||

| Diameter (mm) | Height (mm) | Cylinder Height (mm) | ||

|

SS1418-E20 | 14.2 | 18 | 9.9 |

| SS1622-E20 | 16.2 | 22 | 11 | |

| SS1928-E25 | 19.2 | 28 | 14 | |

|

SX1014-E18 | 10.2 | 14 | 8.0 |

| SX1318-E17Z | 13.2 | 18 | 10.5 | |

| SX1418A-E20 | 14.2 | 18 | 10 | |

| SX1620A-E20 | 16.3 | 19.5 | 9.5 | |

| SX1724-E18Z | 17.3 | 24 | 12.5 | |

| SX1827-E19 | 18.3 | 27 | 15 | |

|

SBX1217-F12Q | 12.2 | 17 | 10 |

| SBX1420-F15Q | 14.2 | 20 | 11.8 | |

| SBX1624-F15Q | 16.3 | 24 | 14.2 | |

|

SP0807-E15 | 8.2 | 6.9 | / |

| SP1010-E20 | 10.2 | 10 | / | |

| SP1212-E18 | 12.2 | 12 | / | |

| SP1515-G15 | 15.2 | 15 | / | |

|

SP0606FZ-Z | 6.5 | 6.05 | / |

| SP0805F-Z | 8.1 | 4.75 | / | |

| SP0907F-Z | 10 | 6.86 | / | |

| SP1109F-VR | 11.3 | 8.84 | / | |

| SP12.909F-Z | 12.9 | 8.84 | / | |

| Able to customize according to size and shape requirement | ||||